Mechanical 7-segment Clock

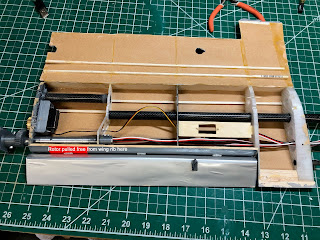

I saw this design on Thingiverse a few weeks ago. I believe it was also featured in Make Magazine's blog. Mechanical 7-segment Display, simple and smooth It's such a cool design that I had to make a clock out of it. Note that the designer, Shinsaku Hiura , also has a full clock made from another of his designs. I printed out 4 copies of the design using Hatchbox and Overture PLA. Instead of painting just the faces of the moving arms I chose to print the entire part in white. The movement is controlled by 4x 9-gram servos . I had a leftover Arduino Nano to control the system. The time is read from a DS3231 real-time clock module and a momentary pushbutton switch is used to switch between the clock and the date. The switch triggers an interrupt in the code and makes the clock change the display to the date (MM / DD) format for 5 seconds before reverting back to the time in 24-hour format. The clock is powered by a 5V USB charger. Note that the servo power comes d